Gate Valve

C.S. Gate Valve

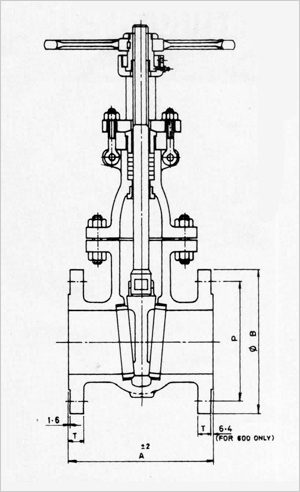

C.S. Gate Valve, O.S & Y Types, Rising Spindle, Bolted Bonnets, Hand Wheel Operate, Flange End to ANSI 150, Body, Bonnets as per ASTM A 216 Gr. WCB, 13% Cr. Working Part, AISI 410 Spindle, Highstensile Studs & Nuts, Spiral Wounds S.S. 304 Graphoil Filled Gaskets, Graphoil Gland Packing, Valves as per API 600 & Tested to API 598

CLASS - 150, 300, 600, 900 & 1500

F.S. Gate Valve

Forged carbon Steel Gate Valve, O.S & Type, Rising Spindle, Bolted Bonnet, hand Wheel Operated, socket Weld / Screwed End, Class – 300 / 800, Body Bonnet as per ASTM A 105, 13% Cr. Steel Working Parts, AISI 410 Spindle, Highstensile Studs & Nuts, Spiral Wound S.S. 304 Graphoil Filled gasket, Graphoil Gland packing, valve as per API 602, Tested to API - 598.

Forged and cast carbon steel gate valve manufacturers and suppliers in Mumbai, India to all over the globe. Cast and forged carbon steel gate valve manufacturer according to international specification and ISO standard certified since 1978 with long lasting, less maintenance and efficient as well as required industrial characteristics and feature to delivered more than expected performance, function and operation.

| PART'S NAME | MATERIALS |

| BODY | ASTM A 216 Gr WCB |

| SEAT RING | CARBON STEEL WITH 13% Cr FACING |

| WEDGE | 216 Gr WCB WITH 13% Cr FACING |

| SPINDLE | AISI 410 |

| BONNET STUD/NUT | ASTM A 193 Gr B7 / ASTM A 194 Gr 2H |

| GASKET | SPIRAL WOUND SS 304 WITH ASBESTOS FILLER |

| BACKSEAT BUSH | AISI 410 |

| BONNET | ASTM A 216 Gr WCB |

| GLAND PACKING | M/C BRAIDED METALLIC WIRE REINFORCED ASBESTOS |

| CROSS BOLT & NUT | CARBON STEEL |

| GLAND BUSH | AISI 410 |

| GLAND FLANGE | CARBON STEEL |

| EYE BOLT & NUT | CARBON STEEL |

| YOKE SLEEVE | ASTM A 439 Gr D2 / SG IRON |

| YOKE NUT | CARBON STEEL |

| GREASE NIPPLE | CARBON STEEL |

| HAND WHEEL | IS 2108 Gr A |

| HAND WHEEL NUT | CARBON STEEL |

| CLASS - 150 | |||||||||||||||||||

|

1 | 1½ | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | |||

| 25 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | ||||

| A | 127 | 165 | 178 | 190 | 203 | 229 | 254 | 267 | 292 | 330 | 356 | 381 | 406 | 432 | 457 | 508 | |||

| B | 108 | 127 | 152 | 178 | 191 | 229 | 254 | 279 | 343 | 406 | 483 | 533 | 597 | 635 | 698 | 813 | |||

| P | 79 | 98 | 121 | 140 | 152 | 191 | 216 | 241 | 298 | 362 | 432 | 476 | 540 | 578 | 635 | 749 | |||

| T | 11 | 14 | 16 | 18 | 19 | 24 | 24 | 25 | 28 | 30 | 32 | 35 | 37 | 40 | 43 | 48 | |||

| CLASS - 300 | |||||||||||||||||||

|

1 | 1½ | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | |||

| 25 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | ||||

| A | 165 | 190 | 216 | 241 | 283 | 305 | 381 | 403 | 419 | 457 | 502 | 762 | 838 | 914 | 991 | 1143 | |||

| B | 124 | 155 | 165 | 191 | 210 | 254 | 279 | 317 | 381 | 444 | 521 | 584 | 648 | 711 | 775 | 914 | |||

| P | 89 | 114 | 127 | 149 | 168 | 200 | 235 | 270 | 330 | 387 | 451 | 514 | 571 | 629 | 686 | 813 | |||

| T | 18 | 21 | 22 | 25 | 28 | 32 | 35 | 37 | 41 | 48 | 51 | 54 | 57 | 60 | 63 | 70 | |||

| CLASS - 600 | ||||||||||||||

|

1 | 1½ | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 | 12 | |||

| 25 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | ||||

| A | 216 | 241 | 292 | 330 | 356 | 432 | 508 | 559 | 660 | 787 | 838 | |||

| B | 124 | 155 | 165 | 191 | 210 | 273 | 330 | 356 | 419 | 508 | 559 | |||

| P | 89 | 114 | 127 | 149 | 168 | 216 | 267 | 292 | 349 | 432 | 489 | |||

| T | 18 | 22 | 25 | 28 | 32 | 38 | 44 | 48 | 56 | 63 | 66 | |||

| TEST PRESSURES IN PSIG | |||

| CLASS | HYDROSTATIC | AIR | |

| BODY | SEAT | SEAT | |

| 150 | 450 | 300 | 100 |

| 300 | 1100 | 750 | 100 |

| 600 | 2175 | 1500 | 100 |

Note:-

- All above mentioned valves can be supplied S.S. 304 / S.S. 316 / Alloy Steel.

- Design Std. : API 600, BS 1414

- Face to Face as per ANSI B 16.10

- Testing Std. : API 598

- End Flanges as per ANSI B 16.5, BS Std., DIN Std.